Materials

Pressure Sensitive Labels

For cans and bottles, typically we choose between Paper or BOPP (biaxially orientated poly-propylene) materials for our pressure sensitive labels.

Paper

- Not used a lot for food/beverage (because of condensation)

- Laminates can be applied to mitigate the effects of condensation

- Tends to be cheaper

Two Primary Paper Options:

A standard for non-food/beverage, this is paper with a thin coating

Use when you want both metallic elements as well as haptic effects (similar to embossing)

BOPP

- Used more often than paper

- Can use laminates or varnishes to protect ink or create texture on label

- More versatile

Three Primary BOPP Options:

Just white; all colors “pop” on white

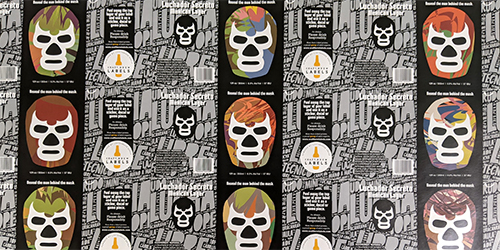

Crystal clear that can show both shiny finish of the can underneath as well as opaque areas with printed white underneath

The material is silver and can be tinted any color; similar to clear, to achieve opaque colors and elements, white can be laid down first in sections

Finishes

Matte: Satisfyingly non-glossy all over varnish or laminate

Gloss: High gloss all over shine

Features

Foiling: Foil or silver ink on only specific areas of a label

UV Ink: Works great for hidden messages or promotions, this ink can only be revealed under a black light

Fluorescent Pink Ink: Creates a special kind of pop on labels, also impressive under a black light

Shrink Sleeves

Technically we have produced both PVC (Polyvinyl chloride) and PET (Polyethylene Terephthalate) shrink sleeves, however recycling regulations and the plastic industry direction are moving away from PVC and towards PET because of recyclability. The chloride portion of PVC can be released as harmful chlorine or HCl gas in certain recycling or disposal methods.

Finishes

Matte: Non-glossy all over varnish

Gloss: Standard gloss all over shine

Features

Fluorescent Pink Ink